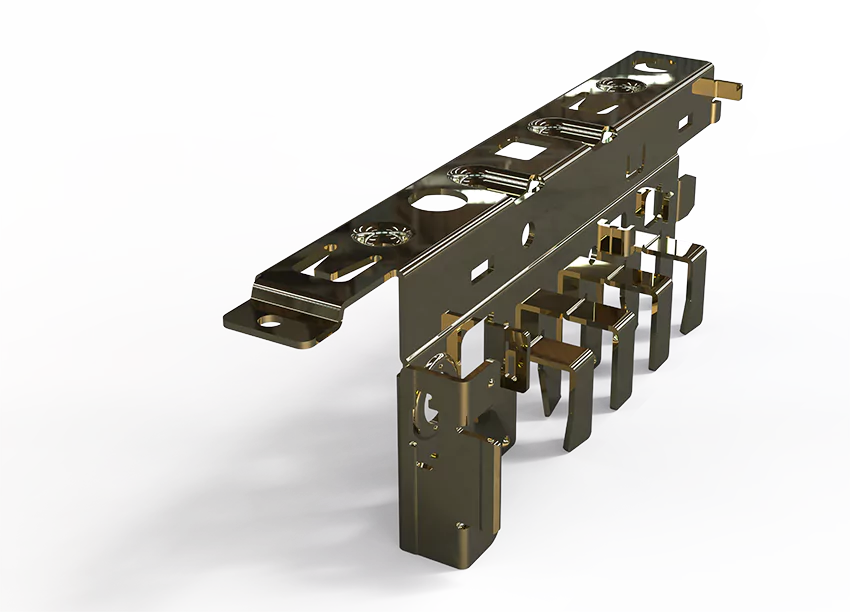

Welcome to Schlegel AG, we are your true specialists for high-precision sheet metal processing through folding, bending, edging, folding, and rounding. Our extensive capabilities in the field of sheet metal processing allow us to meet a wide range of customer requirements.

Latest press brakes for precise results

With our fleet of 15 press brakes from the renowned brands Trumpf, Amada and Beyeler, we are able to precisely process components of various sizes and thicknesses. The working length of our presses ranges from 1200 to 6000 mm and offers a press pressure of 25 to 450 tons. This enables us to manufacture even complex components with the highest precision.

Automated precision and experience

Thanks to modern software, our machines are able to automatically regulate angular deviations. This technology, combined with the many years of experience of our employees, guarantees the highest quality, even for complicated designs.

A wide range of materials for every project

Whether you want to fold stainless steel, bend sheet steel or bend aluminum sheet - we offer a wide range of materials, including stainless steel, mild steel and aluminum. Our experts will be happy to advise you on the right material for your project.

Flexible forming techniques for individual requirements

Our services include sheet metal bending, edging, folding and rounding. With our expertise in sheet metal bending and other forming techniques, we ensure that your components precisely meet your specifications.

Sheet metal processing in Switzerland at the highest level

If you want to bend stainless steel sheet metal, have a special sheet metal bending requirement or want to buy sheet metal in Switzerland - Schlegel AG is your reliable partner. We use our extensive know-how to offer you solutions that meet the highest quality standards.