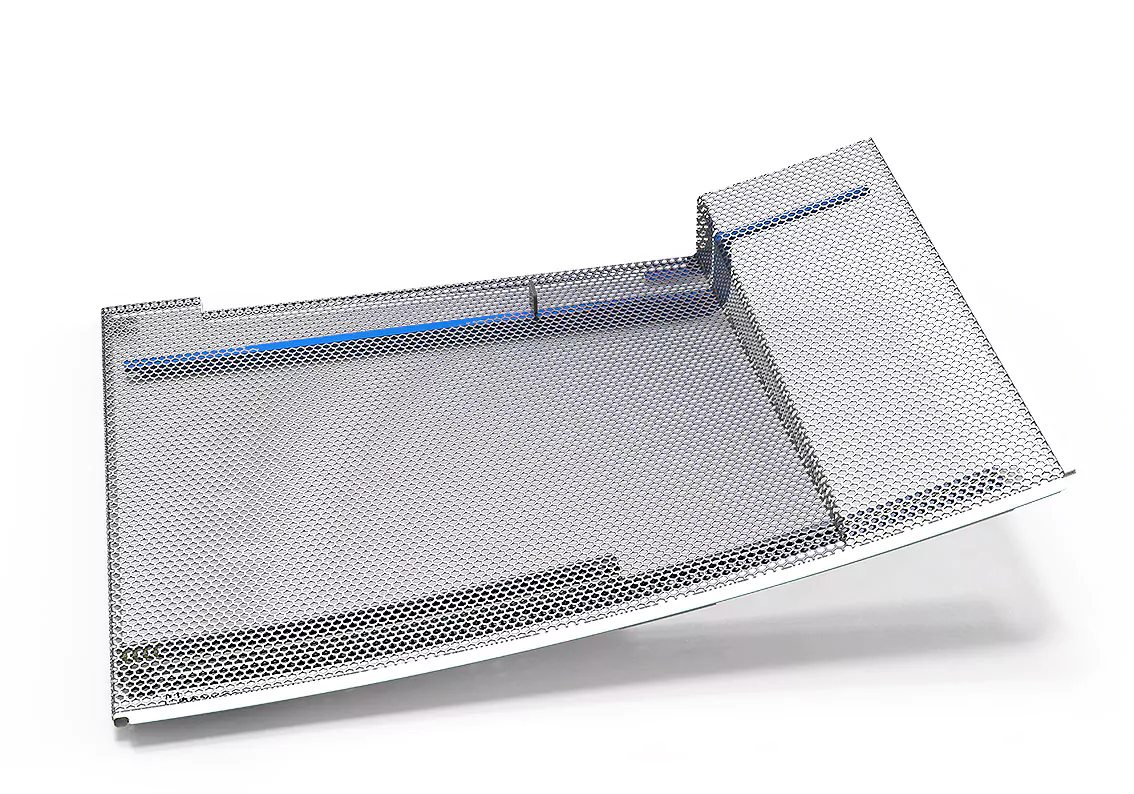

Our company has been offering the production of highly complex sheet metal parts with the most modern laser cutting and punching machines for years. Thanks to our experienced engineers and modern production equipment, we can work precisely and quickly, ensuring the highest possible quality. Automated loading and unloading stations and the ability to run unmanned shifts can guarantee short delivery times. The laser cutting systems are also capable of processing non-ferrous metals such as copper and brass up to 6 mm. In addition, various three-dimensional forming operations such as pull-throughs, threading, stiffening, settling, deep drawing, etc. are possible on our combination machines. We work with materials such as mild steel and stainless steel up to 12 mm and also offer sheet metal stamping.

Laser cutting, Tru Laser 5030 fiber

Working areas: 3000 x 1500 mm

Punching, Amada EMZ 3610 NT PDC

Working range: 3000 x 1500 mm

Processing with combined punching and laser cutting machine, Trumatic 7000

Working area 3000 x 1500 mm

Special feature: various three-dimensional forming such as pull-throughs, threads, stiffening, settling, deep drawing, etc. are possible.

Mild steel up to 12 mm

Stainless steel up to 12 mm

Structural steel up to 12 mm

Also: non-ferrous metals like copper and brass up to 6 mm can be cut with the laser.

Feel free to contact us if you need professional sheet metal laser cutting, metal stamping or sheet metal embossing.