Clamping devices are becoming increasingly important. Especially with regard to smaller series, a clamping device can pay off. For Gastrofrit AG, a member of the group, a jig has been developed that brings several innovations.

Until now, the fryer pans were conventionally made of chrome steel. In practice, this meant manual welding and then electropolishing of the visible inner surface. More recently, the mirror chrome steel pan is laser cut from a sheet of metal. In the following step it is carefully beveled and then welded with the in-house laser. This conserves the material and saves the electropolishing operation. Costs and resource utilization are reduced.

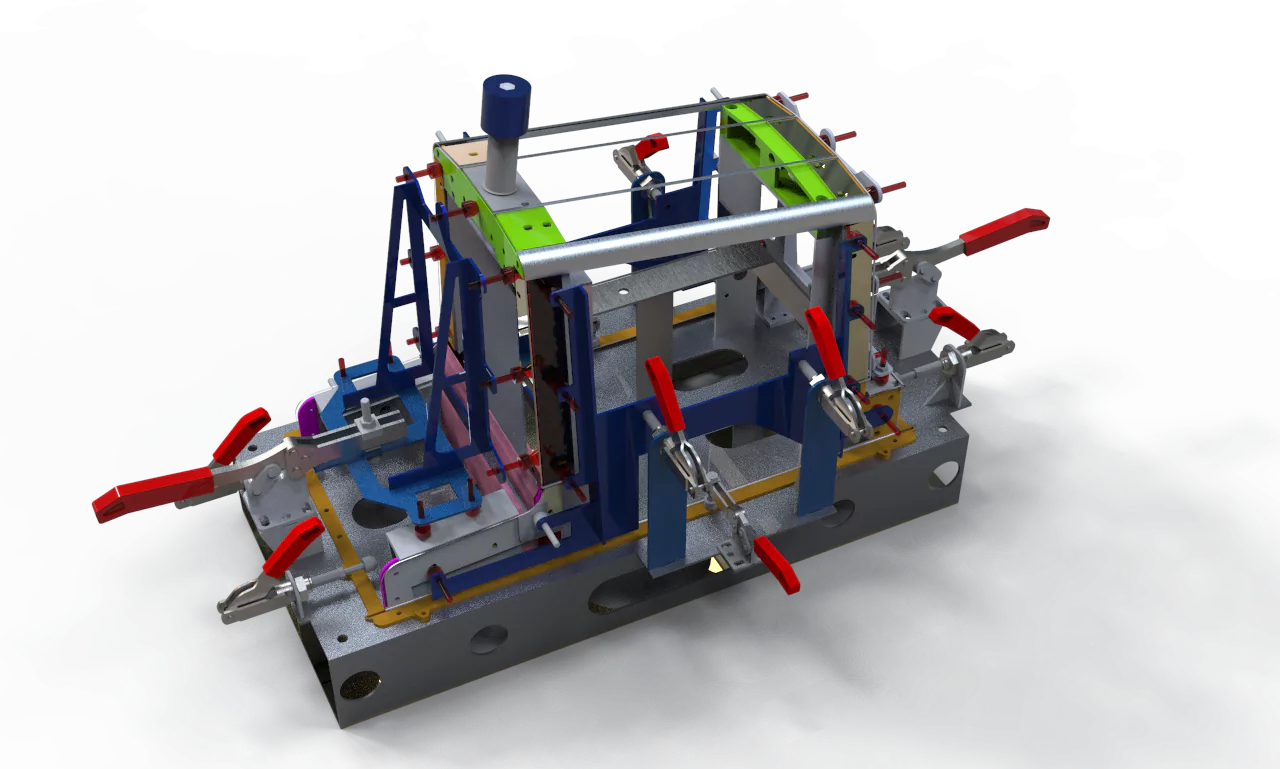

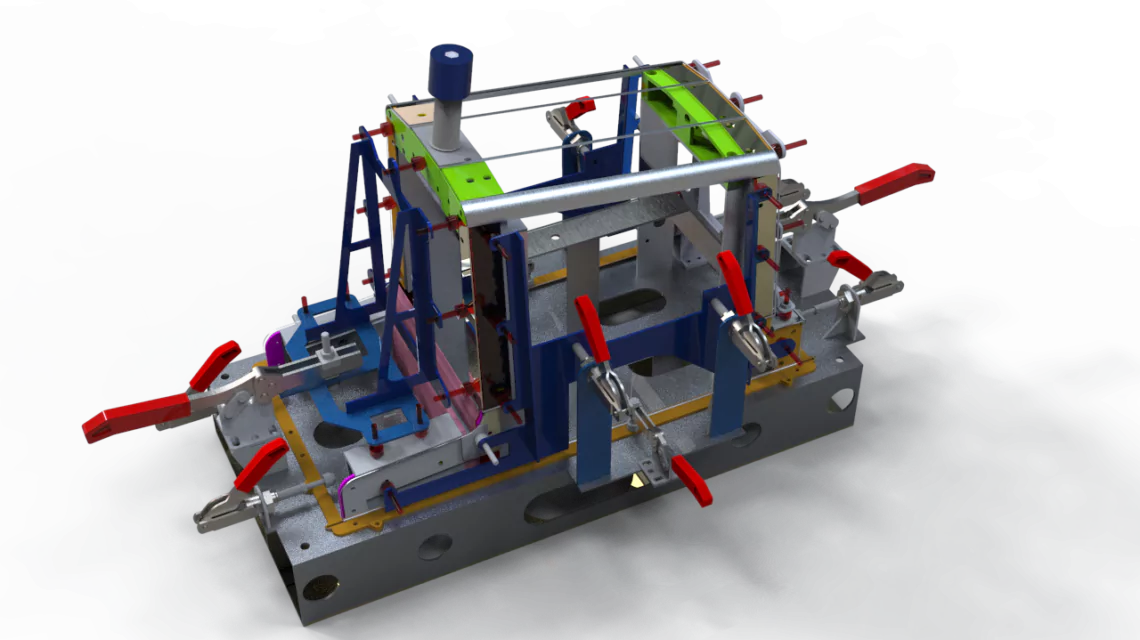

The fixture was developed on CAD and assembled with plastics from the D3 printer. At the laser weld, H2O flows out of nozzles to prevent discoloration and ensure that the weld reaches the highest quality level. The laser welding robot located in the Radom plant needs 32 seconds for the seam of 2.2 meters.

Contact Person Schlegel Gruppe

Alexander Schlegel

Schlegel AG

Blumenfeldstrasse 14

CH-9403 Goldach

Tel: +41 71 855 80 70

Mobile: +41 79 431 45 02

Email: alexander@schlegel.ch