Sheet metal processing in Switzerland: precision and efficiency to perfection

For years, our company has established itself as a pioneer in sheet metal processing and sheet metal fabrication in Switzerland. With the highest level of commitment and technological expertise, we realise sheet metal work that is second to none in terms of quality and precision.

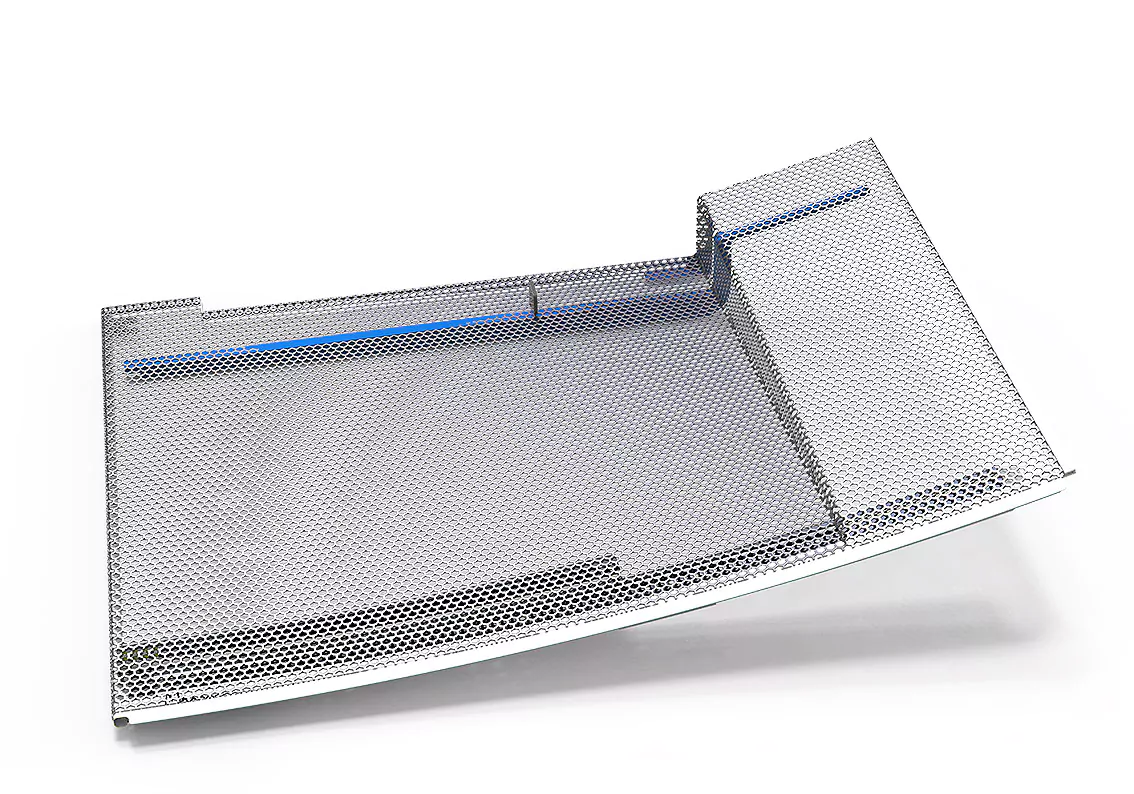

Highly complex moulds - precise and fast

Our dedicated engineering team designs and develops parts that are cut to size using laser or automatic punching machines. Accuracy takes centre stage. By using automatic loading and unloading stations on our machines, we can not only work in unmanned shifts but also guarantee impressive speed and efficiency in sheet metal production.

Wide range of processing options

Laser cutting, Tru Laser 5030 fibre

Working areas: 3000 x 1500 mm

Punching, Amada EMZ 3610 NT PDC

Working area: 3000 x 1500 mm

Processing with combination machine punching and laser cutting, Trumatic 7000

Working area 3000 x 1500 mm

Speciality: Various three-dimensional formings such as pull-throughs, threads, reinforcements, offsets, deep-draws, etc. are possible.

Selection of the best material

Mild steel up to 12 mm

Stainless steel up to 12 mm

Mild steel up to 12 mm

in addition: non-ferrous metals such as copper and brass up to 6 mm can be cut with the laser.

Sheet metal drawing and more: The full range of sheet metal processing in Switzerland

Our portfolio includes not only cutting and forming, but also additional services in the field of sheet metal drawing and sheet metal processing. As a renowned sheet metal processor from Switzerland, we stand for quality, reliability and on-time delivery.

If you are looking for an expert in sheet metal processing in Switzerland, Europe or for global projects who masters all facets of sheet metal processing, you have come to the right place. Get in touch and experience what is possible in modern sheet metal processing. We look forward to receiving your non-binding enquiry in our order centre